SUSTAINABILITY

Sustainability is achieved through recovering of the raw materials contained in the end-of-life tires (ELTs). This recovered material can be used as a substitution for fossil-based resources and enables a holistic positive CO2 footprint. CO2 emissions from conventional industrial Carbon Black production amount to 35 million tons a year. Pyrolytec can achieve a positive CO2 footprint and savings of 72,000 tons of CO2 equivalents a year through using the unique batch pyrolysis technology.

PYROLYTEC`S VISION

Recovering valuable raw materials from 31 million tons of ELTs per year worldwide constitutes a market with huge untapped economic potential. Pyrolytec has set itself the goal of realising the recovery of this potential which has so far remained ecologically and sustainably unused.

The tire industry takes 70% of the entire conventional Carbon Black production which becomes available again as potential feedstock in the form of ELTs. This results in an annual ELT volume of 3.5 million tons p.a. in Central and Eastern Europe.

This potential should not go to waste, which is why Pyrolytec has set itself the goal of becoming among the largest producers of recovered carbon black within the next ten years.

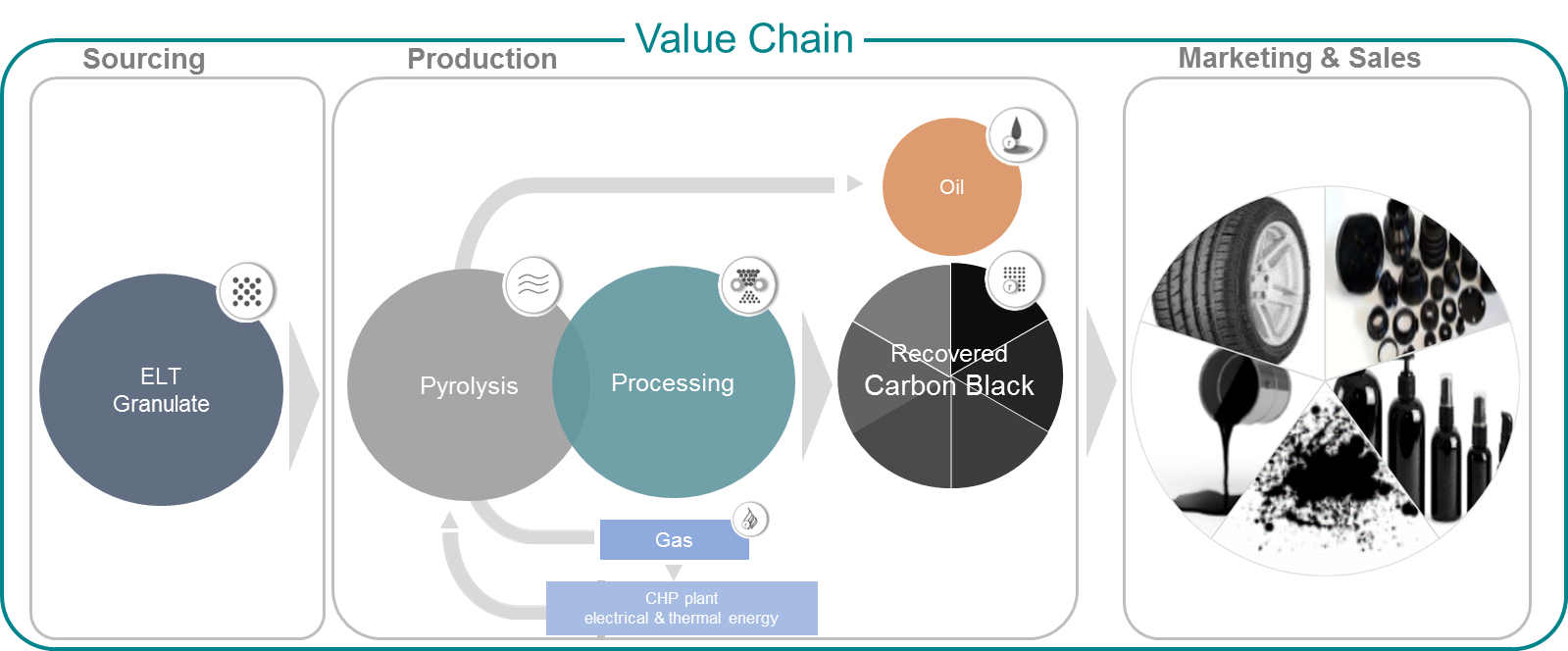

VALUE CHAIN

The manufacturing process entails carbonization as the basis of the production process during which pure intermediates are produced from ELT shreds to a consistently high standard. In the post-processing step, the semi-finished product goes through the process of de-agglomeration, pelletizing and drying to produce high-grade products for the respective application-specific areas. The production know-how developed over more than a decade resides above all in the operation and handling of the formulations for the various products and applications. Moreover, byproducts such as oil and gas are recovered from the carbonization process. Gas as the source of energy is fed directly into the CHP and used by the processes as electrical and thermal energy. The tire pyrolysis oil (TPO) contributes to profitability through its sale to the chemical industry.

CARBON BLACK MARKET SEGMENTS

The properties of the recovered carbon black products allow them to be sold in selected specialty markets of the carbon industry, which are different from the mass market of tire production.

The target segments in the field of coatings, plastics, and color pigments are characterized by:

- Significantly shorter sales cycles and application tests than in the tire industry.

- More specific requirements for the properties of carbon black products.

- Significantly higher prices due to extensive independence from the price of oil.

Due to their unique selling points, upcycled carbon black products can be placed more competitively in these market segments and achieve higher margins than conventionally produced carbon black products.

Pyrolytec’s application-oriented production of rCB enables it to serve different product segments with the highest CB quality. The first plants are designed to produce for the high-priced CB niche markets of plastics, paints and coatings. Further plants will additionally serve the tire and technical rubber goods (TRG) market, which is almost ten times larger, once greater economies of scale have been achieved.

The key unique selling points of the products are the low PAH content, high color strength, excellent reinforcing properties, higher mechanical abrasion resistance, dynamic performance, and excellent weather and UV resistance.

Dr. Frank Deisel | CEO

Florian Herzog | COO

VACANCIES

Are you looking for a new challenge?

Pyrolytec is always looking for qualified specialists to strengthen its team.

Please find the vacant positions to the right.

If you think you would be a beneficial team-member to Pyrolytec,

but there is currently no job-opening fitting your personal skills,

please get in touch!

Dr. Frank Deisel

f.deisel[at]pyrolytec.de

Fulltime:

Get in touch with us!

Parttime:

Get in touch with us!

Pyrolytec Green Solutions GmbH

Registered Office

Hochriesstrasse 47a

83209 Prien

Germany

Tel: +49 89 2000 14 51 – 0

Fax: +49 89 2000 14 51 – 99

info[at]pyrolytec.de